The evolution of Brand expanding from boards collection to Sails and related rig components such as Masts and Booms, makes me feel very confident as my technical background experience comes from several years of sails and mast designing together with boards developments.

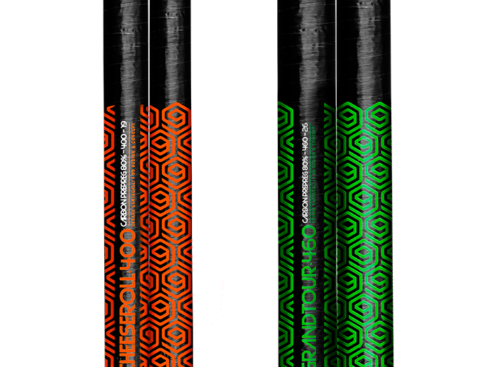

When it came to choose the Mast manufacturer I had no doubts about my choice.

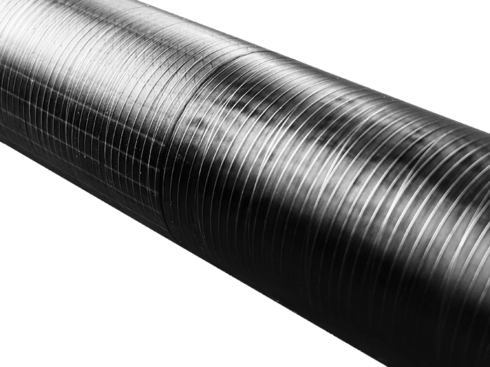

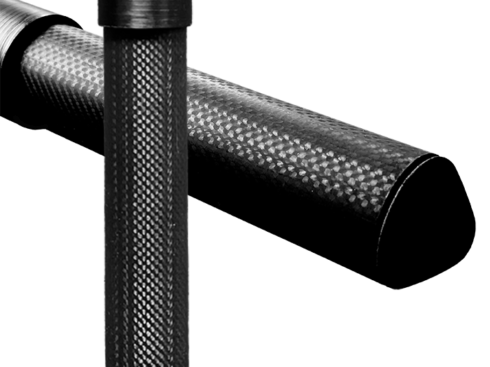

For over 6 years I worked in Reglass factory and contributed to their first ever 100% Prepreg-carbon Technology developments and expansion to the market.

It is a personal honor to proudly mark my masts with a “Made in Italy” label, as well as being given the privilege to closely develop and produce my personal Branded mast at Reglass which I consider family and a true excellence of quality and technology to stand above any level available today in our industry.